ANKO's Automated Samosa Pastry Machine Boosts Productivity for a Kuwait Client's Samosa Production

A production process of samosa pastry starts from repeatedly rolling out pastry, then stacking in a pile, separating one by one, striping pastry. The complex process spends a lot of time and labor costs. ANKO's Samosa Pastry Sheet Machine can hourly produce 16,200 pieces of samosa pastry with standard size and automatically stack in piles. Also, the thickness is adjustable as desired. That results in considerable saving in labor costs. In addition, the machine can produce both spring roll pastry and samosa pastry which helps the client develop a new product line and bring business opportunities. The investment is of great worth, relatively.

Samosa Pastry

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. The gluten was too high in the client's pastry recipe so that the pastry excessively shrank. Through the change of ingredients and the spray nozzle, the final products met client's requirements.

Basically, SRP Series only produces pastry with cake flour. In this case, the flour protein content in client's recipe was above 11% which led to shrinkage. Moreover, after stirring, lumps easily happened and stuck in the spray nozzle.

To solve the problem, firstly, we used flour with lower protein to minimize shrinkage, but the size of pastry still could not achieve the demand of 210 mm in width.

Then, we tried another method to prevent shrinkage, which is to customize a wider spray nozzle. Through precise calculation, we increased the length of spray nozzle in accordance with the shrink percentage so that the products would not be smaller than 210 mm even shrink.

Solution 2. Handmade samosa pastry is heavier than machine-made, but heavy pastry will affect the smoothness of the stacking process. ANKO's engineers would like not only to remain the weight as same as the traditional ones, but also make a stacking device run smoothly, so we had a perfect method to achieve.

We appreciate that clients are looking forward to having consistent food quality when they transfer business from manual food production to machine, for they would like to avoid the risk of losing existing customers. As for the case, we faced the problem mentioned above. In order to make heavier pastry, ANKO engineer used ...(Please contact us to get more information)

Food Equipment Introduction

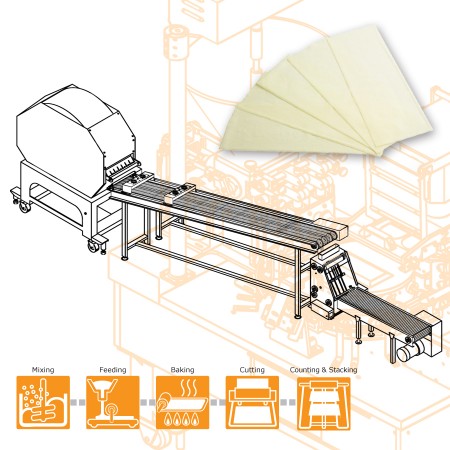

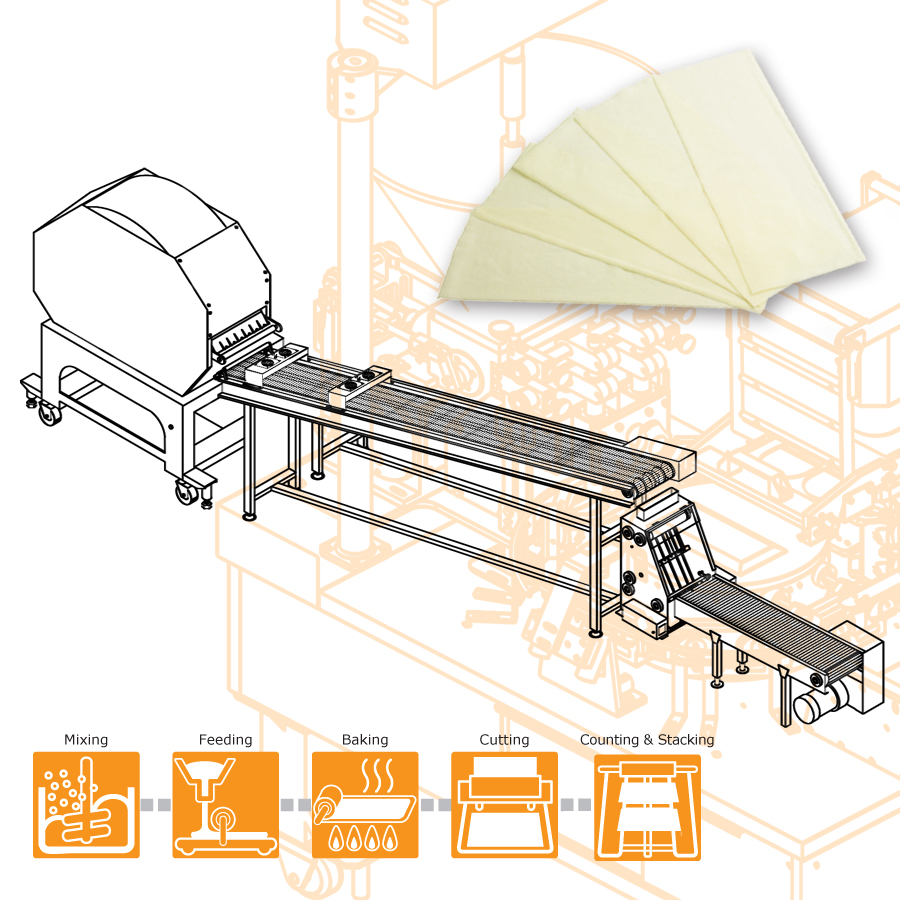

- Pour well-stirred batter into the hopper.

- Adjust settings on the control panel and make sure the temperature and condition of baking drum.

- Bake batter into a belt of pastry.

- Straightly trisect the belt of pastry.

- Cool them by fans.

- Cut into required length.

- Stack pastry

- Manually tear pastry along trisected lines by hand.

As pastry with different specifications is in demand, double-line production not only enables a large increase in production capacity, but also can produce all of them together.

Some retailers sell both spring roll pastry and samosa pastry, and pastry specifications are with slight differences. The manufacturer is unlikely to achieve efficient production and diversification as the baking drum and stacking device have to change all the time. Therefore, the innovative design of SRP-90DA enables the manufacturer to easily change spray nozzles with different widths and use corresponding stacking devices, different combinations for different specifications.

The spray nozzle is elaborately located to full utilize the surface of a baking drum. This design shortens the waiting time, makes the operation more effective and the change of spray nozzle easier.

What's the purpose to locate a spray nozzle beneath a baking drum, close to the height of knees.

For mass production, we don't waste any minutes for only waiting so that the size of backing drum as well as the cooking temperature and time are calculated to make batter keep spreading onto the baking drum. Batter is cooking while the baking drum is rotating. As it turns a two thirds circle, batter is cooked into a belt of pastry that is scraped from the baking drum. Then, the rest of one third circle is for re-heating to bake the following pastry. In other words, if the spray nozzle is located at other place, for example, above the baking drum, it may need higher power or it may leave too much unused surface to reduce production efficiency.

Moreover, the height of the spray nozzle close to knees makes replacement more convenient. Users do not have to climb ladders up and down. The brilliant design achieves the possibilities of small batch production and product diversification.

- Solution Proposal

Quality Samosa Pastry Production with ANKO's One-Stop Solution

ANKO did

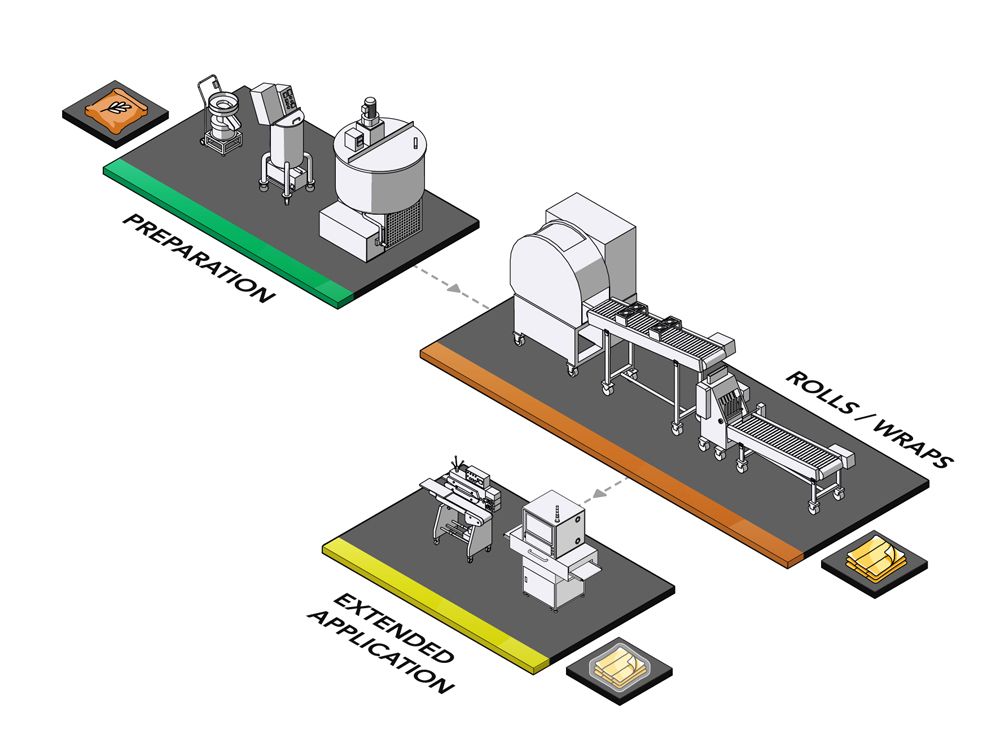

ANKO’s SRP Automatic Samosa Pastry Machine can greatly reduce your labor costs and increase the production volume of up to 16,200 Samosa Pastries per hour, while solving labor issues and rising wages. To increase the level of automation, we can also plan Samosa Pastry Integrated Production Solution for you according to the real needs.

ANKO can help you more

The Better Mixer and Batter Storing, Cooling and Resting Tank are optional to make smooth batter. ANKO also offers packaging machines for the frozen food industry and food X-ray inspection machines to increase food safety standards.

According to your demand, we will recommend a solution that is suitable for you. If you are interested in more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SRP Series Automatic Spring Roll and Samosa Pastry Sheet Machine

Spread batter on a pan, cook in a short time, form a sheet of pastry or variants. As long as the food is cooked like the above process, SRP Series machine can manufacture it such as spring roll pastry, samosa pastry, crepe, etc. The machine bakes pastry, cuts it into pieces, then stacks them in piles as required numbers. If SRP Series connects with a wrapping machine or depositor, its function will be more than a pastry making machine but an automatic/semi-automatic spring roll production line (SR-27/SRPF). In this case, SRP-90DA incorporates double-line production to boost production capacity up to 16,200 pcs/hr.

- Video

SRP Series machines are multipurpose pastry making machines, square pastry for spring roll or rectangular pastry trisected by rotary cutters for samosa. This video introduces machine production from pastry baking, cooling, cutting to stacking in which it is obvious that food quality made by machine is not inferior to hand-made ones. Moreover, machine production saves time, labor costs and creates benefits from productivity.

- Country

Kuwait

Kuwait Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

Samosa with delightful small triangular shape is a common appetizer in Indian restaurants. Mashed potato, vegetable, and minced meat wrapped with crispy crust is also one of popular street snacks and a best choice for satisfying your hunger. Some people use a strip of thin pastry and make layers by folding a couple of triangles; some people prefer thick pastry, fill up stuffing into a pastry cone and then seal its top.

Traditionally, samosa is deep fried, but now, baking is available for health.- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Baking Powder/Oil/Salt/Water

How to make

(1) Combine flour, baking powder, and salt in a bowl. (2) Add oil and well mix them. (3) Pour water and knead dough until it becomes elastic. (4) Cut out equal portions of dough balls. (5) Roll out each of them into thin and round pastry. (6) Take one piece of pastry, smear oil and sprinkle some flour on its top. And then cover with another pastry. (7) Repeat the last step to stack them in a pile. (8) Apply a rolling pin to roll out them again until they are thin enough. (9) Strip pastry for wrapping filling later.

- Downloads

English

English